A Safer Load for Steel

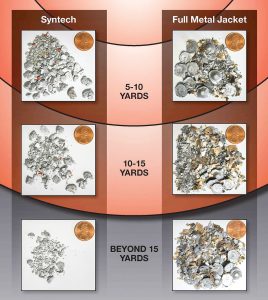

Another benefit of a polymer-encased projectile is how it minimizes splash-back on steel targets, which is increasingly important when shooting your PCC at reactive targets. We often ignore the physics involved when shooting a jacketed bullet into a hard steel target mere feet away. The reality is that pieces of the copper jacket and larger fragments of lead core deflect off the target upon impact and can disperse fragments up to 15 yards from the target. With no hard copper jacket and a soft lead core, Syntech simply produces less of this splash back, and what it does produce travels shorter distances when fired at steel targets.

We talked with several ballisticians at Federal about the testing they conducted to back up their reduction of splash-back claims. Product Development Engineer, John Swenson explained how they came to these conclusions. “We set up a test where a shooter fired 100 rounds of common, commercial, 115-grain FMJ, TMJ and Syntech ammunition from a distance of 23 feet at a steel target.” Swenson said.

For the test, Swenson said his team covered a 15-yard radius in front of the target with a large tarp, on which they marked 5-, 10- and 15-yard circles. After shooting each type of ammunition, they collected bullet fragments in the 10- and 15-yard marked areas. These fragments were then weighed and analyzed.

“Not only did Syntech produce less overall weight in recoverable fragments than typical FMJs, but most of the fragments were smaller and traveled shorter distances after impacting the steel,” stated Swenson.

Syntech produced 51-percent less total recoverable fragment weight than FMJs between 5 and 15 yards from the target. It also resulted in 91-percent less weight in fragments traveling more than 15 yards from the target, and 77-percent less in fragments weighing more than 10 grains.

See it at your gun shop, or contact Federal Premium; Tel.: (800)-379-1732; Web: www.federalpremium.com